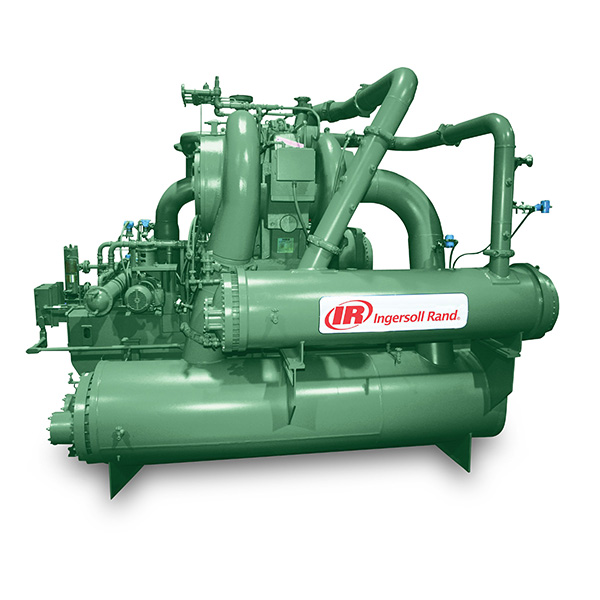

MSG®TURBO-AIR®整体齿轮传动离心式压缩机MSG®TURBO-AIR® Integral geared centrifugal compressor

MSG Turbo-air compressors offer excellent design flexibility. MSG compressors are applied in engineering with many available configurations:

Flow rates from 70 to 3800 m3 / min (2500 to 135,000 CFM)

Input capacity over 18,650 kW (25,000 hp)

Discharge pressure up to 100 bar (1450 lb/sig)

Oil-free air and natural gas prevent system contamination

Reduce the possibility of compressed air line fires caused by oil residue

There is no expensive waste disposal associated with oily condensates

Eliminates the cost and maintenance of oil separation filters during discharge

High reliability

MSG Turbo-air centrifugal compressor design is very

Reliable because:

Conservative high quality gear design

Long life pinion bearing design

Absorb thrust load at low speed

Stainless steel compression element

Low compressor operating life cycle cost

The MSG TURBO-AIR centrifugal compressor offers better overall operating efficiency than positive displacement or other centrifugal compressors.

Excellent efficiency at full load, partial load and no load

Low maintenance cost

High reliability design increases uptime (limiting the need for multiple unit installations for basic reliability reasons)

During the compression process, there are no sliding or rubbing parts, which can lead to wear and thus reduce efficiency

class-0-centrifugal

Simple operation/maintenance

State-of-the-art MAESTRO control system

Fully automatic operation for all process conditions

Machine self-diagnosis

Compression elements are wear free and do not require regular replacement

Barrier-free horizontal split transmission for quick inspection

Removable intercooler and aftercooler bundle for easy cleaning

Simple installation

Compressors, lubrication systems, intercoolers, couplings, coupling protection, connecting pipes, etc. on a common basis

Easy to install, no special basic requirements

Easy access component

Site connection point flexibility

Footprint reduction

The dynamic compression process is pulsation-free, so there is no need to install additional damping equipment.

The MSG turbo-air centrifugal compressor has a unique design.

One, two or three rotors, with up to six stages per gearbox

Horizontal divider for easy access to parts

Air current

Engineering air applications industrial gases

Instrument air

American Petroleum Institute (API) standards

Coal ash blower

Large factory air

Power industry related

Gas compressor application

Gas supercharging

Natural gas gathering and transportation

Hydrocarbon refrigerating gas

Carbon monoxide

Carbon dioxide (wet and dry)

Synthetic gas

Low molecular weight circulating gas

High-pressure nitrogen

Landfill gas

Air flow arrangement

The MSG turbo-air centrifugal compressor features an advanced arrangement of gas flow components. The advantages of this arrangement include:

Directional gas movement to reduce friction caused by turbulence

The air is cooled after each stage to provide high isothermal efficiency

Flow chart

01: compressor inlet

02: First stage compressor volute

03: Coolant enters

04: Coolant extinguished

05: First stage intercooler

06: two-stage compressor volute

Second stage intercooler

08: three-stage compressor volute

09: compressor emission